The Hossfeld Bender Manual is a comprehensive guide essential for understanding and utilizing the machine effectively. It covers setup, operation, and maintenance for models like No. 1 and No. 2, ensuring safety and efficiency in bending tasks.

1.1 Overview of the Hossfeld Bender

The Hossfeld Bender is a versatile machine designed for bending metal, iron, and other materials. Available in models like No. 1 and No. 2, it caters to various projects, from simple bends to complex tasks. Known for durability and precision, it supports tasks in workshops, factories, and job shops. Accessories like the Bulldozer Die enhance its capabilities, making it a reliable tool for diverse bending needs. Its universal design ensures compatibility with multiple materials and applications.

1.2 Importance of the Manual for Operation and Maintenance

The Hossfeld Bender Manual is crucial for safe and effective operation. It provides step-by-step instructions, troubleshooting tips, and maintenance schedules to ensure optimal performance. Users can learn proper setup, understand safety guidelines, and explore advanced features. Regular maintenance tasks outlined in the manual prevent wear and tear, extending the machine’s lifespan. By following the guide, operators can maximize efficiency, avoid errors, and ensure reliable results in various bending projects.

Key Features of the Hossfeld Bender

The Hossfeld Bender is renowned for its durability and versatility. It offers model variations like No. 1 and No. 2, compatibility with diverse materials, and unique tooling options.

2.1 Model Variations (No. 1, No. 2, etc.)

The Hossfeld Bender is available in multiple models, including the No. 1 and No. 2, each designed for specific tasks. Model No. 1 is ideal for basic bending needs, while Model No. 2 offers advanced capabilities for complex projects. These variations ensure users can choose the right tool for their workload, whether for small-scale metalworking or heavy-duty applications in industrial settings. Each model is built with durability and versatility in mind, catering to diverse workshop requirements.

2.2 Compatibility with Different Materials and Projects

The Hossfeld Bender is exceptionally versatile, capable of bending various materials such as metal, iron, and flat stock. It excels in projects ranging from metalworking and wrought iron fabrication to autobody repairs and general job shop tasks. Equipped with specialized tooling, it can perform tasks like square bends, tube bending, and flat stock bending with precision. This adaptability makes it a valuable asset for workshops needing to handle diverse materials and projects efficiently.

2.3 Unique Tools and Accessories Available

The Hossfeld Bender offers a range of unique tools and accessories to enhance its functionality. The Flat-Face Radius Block enables precise bending of flat stock, while the Bulldozer Die is ideal for creating square bends. Additionally, the 180 Tube Die allows for perfect tube bending. These specialized tools expand the machine’s capabilities, making it suitable for a variety of projects, from metal fabrication to autobody repairs. Optional accessories further tailor the Bender to specific tasks, ensuring versatility and efficiency in different workshop environments.

Understanding the Hossfeld Bender Manual

The manual is structured to guide users through installation, operation, and maintenance, with clear sections and diagrams ensuring comprehensive understanding and safe usage of the Hossfeld Bender.

3.1 Structure and Organization of the Manual

The Hossfeld Bender Manual is meticulously organized into sections, each addressing specific aspects of the machine. It begins with an introduction, followed by installation and setup instructions. Detailed operational guidelines are provided, including both basic and advanced techniques. Maintenance and troubleshooting sections ensure longevity and efficiency. The manual concludes with safety guidelines and resources for further support. This clear structure ensures users can easily navigate and find the information they need, making it an indispensable resource for both novices and experienced operators. The inclusion of diagrams and visual aids further enhances comprehension, while the comprehensive index allows for quick access to specific topics. Overall, the manual’s logical flow and thorough coverage make it an essential tool for maximizing the Hossfeld Bender’s capabilities.

3.2 Key Sections Every User Should Review

Every user should review the installation and setup guide to ensure proper machine assembly. The operational section provides essential instructions for basic and advanced bending techniques. Safety guidelines are critical to prevent accidents and ensure safe handling. Maintenance routines are outlined to prolong the machine’s lifespan, while troubleshooting helps resolve common issues. Accessories and compatibility sections expand functionality, and historical background offers insights into the machine’s evolution. These sections collectively ensure efficient, safe, and effective use of the Hossfeld Bender. Regular updates are recommended for optimal performance and adherence to safety standards.

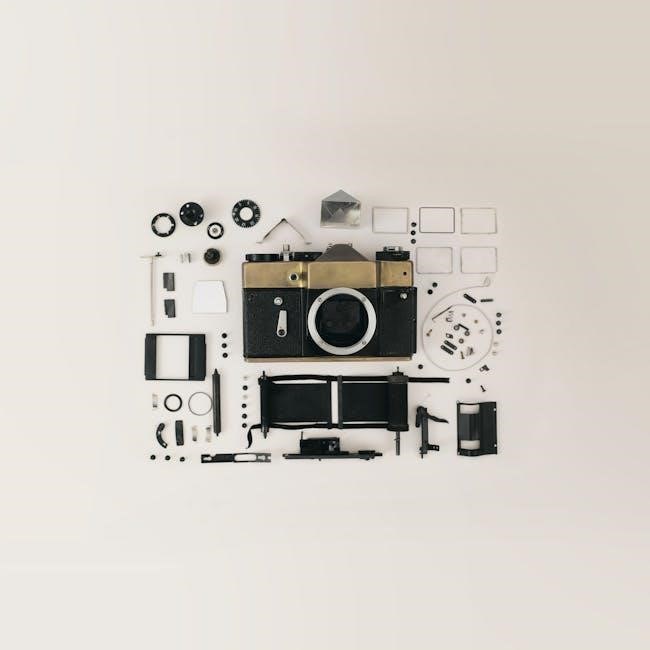

3.3 Visual Aids and Diagrams for Better Comprehension

The manual includes detailed visual aids and diagrams to simplify understanding of complex procedures. Illustrated instructions guide users through assembly, operation, and maintenance. Diagrams highlight key components, ensuring accurate identification and proper usage. Step-by-step visuals for bending techniques and troubleshooting common issues enhance clarity. These resources cater to different learning styles, making the manual accessible to both novice and experienced users. High-quality images and clear labels further aid in comprehension, ensuring safe and effective use of the Hossfeld Bender. Visual aids are integral to maximizing productivity and safety.

Installation and Setup Guide

Installation is quick and easy using just four bolts, with simple instructions provided. Changing from power to manual operation is straightforward, ensuring a smooth setup process always.

4.1 Step-by-Step Installation Instructions

Begin by unpacking and inventorying all components. Ensure the installation site is level and clear. Mount the machine using the provided four bolts, following the illustrated guide. Secure the base firmly to prevent movement. Connect power according to the manual’s wiring instructions. For manual operation, attach the handle as directed. Install any additional tooling or accessories. Double-check all connections and alignments before powering up. Test the machine with a small bend to confirm proper setup and functionality.

4.2 Required Tools and Hardware for Setup

For proper installation, gather essential tools like wrenches, screwdrivers, and a level. Ensure you have the provided bolts for securing the machine. Use a wrench to tighten base mounts and connections. Additional tools like clamps or pliers may aid in aligning components. Refer to the manual for specific hardware requirements. Ensure all parts are genuine to maintain compatibility and performance. Having these tools ready will streamline the setup process and ensure a secure installation.

4.3 Tips for a Smooth and Efficient Installation Process

Ensure a clean, flat work surface for installation. Follow the illustrated instructions step-by-step. Pre-check all bolts and hardware before starting. Use a level to ensure proper alignment. Tighten connections gradually to avoid misalignment. Keep additional tooling sets organized for easy access. Refer to the manual for specific torque requirements. Avoid over-tightening to prevent damage. Maintain a tidy workspace to reduce setup time. Double-check connections before powering up. Consider additional clamps or supports for stability during operation.

Operating the Hossfeld Bender

The Hossfeld Bender Manual provides a step-by-step guide for operating the machine, covering basic and advanced functions, safety protocols, and tips for efficient bending tasks.

5.1 Basic Operations and Controls

Mastering the Hossfeld Bender’s basic operations ensures smooth functionality. Begin by familiarizing yourself with the control panel, which features intuitive levers and buttons for adjusting bends. The manual details how to set up the machine, select the correct dies, and perform simple bends. Always refer to the provided diagrams for clarity. Proper alignment and secure clamping of materials are crucial for precise results. Start with a test run to ensure everything operates as expected before proceeding to actual projects. Safety is paramount, so never bypass protective features. Regularly review the manual to maintain proficiency and explore advanced techniques gradually. This approach ensures optimal performance and longevity of the machine.

5.2 Advanced Techniques for Complex Bends

For intricate bends, the Hossfeld Bender offers advanced techniques using specialized tools like the Flat-Face Radius Block and Bulldozer Die. These tools enable precise control over complex shapes, ensuring accuracy and consistency. The manual provides detailed guidance on configuring the machine for multi-angle bends and handling thick or hardened materials. Users can achieve 180-degree bends with the Tube Die, while optional adapters expand versatility for unique projects. Always consult the manual for specific setup instructions to master these techniques effectively.

5.3 Safety Precautions During Operation

Always wear protective gear, including gloves and safety glasses, when operating the Hossfeld Bender. Ensure loose clothing or jewelry is secured to avoid entanglement. Keep children and unauthorized individuals away from the machine. Regularly inspect tools and dies for damage, and never operate the bender near flammable materials. Follow manual guidelines for load limits to prevent overload. In case of emergencies, disconnect power immediately. Proper training and adherence to safety protocols are essential to prevent accidents and ensure safe, efficient operation.

Maintenance and Repair

Regular lubrication of moving parts and thorough cleaning are essential. Inspect dies and components for wear and follow manual guidelines for timely repairs to maintain efficiency.

6.1 Regular Maintenance Tasks

Regular maintenance is crucial for optimal performance of the Hossfeld Bender. Lubricate moving parts periodically to prevent wear and ensure smooth operation; Clean the machine thoroughly after use to remove debris. Inspect dies and components for signs of wear or damage. Refer to the manual for specific maintenance schedules and guidelines. Always follow recommended procedures to maintain accuracy and extend the machine’s lifespan. Proper upkeep ensures reliability and consistency in bending operations.

6.2 Troubleshooting Common Issues

Troubleshooting the Hossfeld Bender involves identifying common issues like improper alignment or excessive wear. Check for misaligned components and adjust accordingly. Inspect dies for damage or wear and replace if necessary. Lubricate moving parts if stiffness occurs. Refer to the manual for diagnostic procedures. Addressing issues promptly prevents further damage and ensures efficient operation. Regular inspection and timely repair are key to maintaining the machine’s performance and longevity. Always follow the manual’s guidelines for resolving specific problems effectively.

6.3 Repair Procedures for Wear and Tear

Repairing wear and tear on the Hossfeld Bender involves replacing worn components like dies, bushings, and pins. Inspect for excessive wear or damage and substitute with genuine parts. Lubricate all moving parts to prevent friction. Tighten loose fasteners and ensure proper alignment. For bent components, carefully straighten or replace them. Refer to the manual for specific torque specifications and diagrams. Regular maintenance and timely repairs extend the machine’s lifespan and maintain optimal performance. Always use authentic Hossfeld parts for reliability and durability.

Accessories and Tooling

The Hossfeld Bender offers essential tools and accessories to enhance functionality. These include dies, bushings, and specialized tooling sets for diverse bending tasks, ensuring versatility and precision.

7.1 Essential Tools for Expanded Capabilities

The Hossfeld Bender is complemented by essential tools that broaden its functionality. These include dies, radius blocks, and specialized bending attachments. The Bulldozer Die, for instance, enables precise square bends, while the Flat-Face Radius Block ensures consistent results. Additional tooling sets, like the 180 Tube Die, cater to specific bending needs. These tools enhance versatility, allowing users to tackle a wide range of projects with accuracy and efficiency. They are available as optional accessories to maximize the machine’s potential for various metalworking tasks.

7.2 Optional Accessories for Specific Tasks

Optional accessories for the Hossfeld Bender provide specialized functionality tailored to specific tasks. These include specialized dies, radius blocks, and adapters designed for intricate bends or unique materials. For instance, the 180 Tube Die enables precise bending of tubes, while custom dies can handle uncommon shapes. These accessories allow users to expand the machine’s capabilities, ensuring versatility for a wide range of projects and materials, making the Hossfeld Bender adaptable to diverse metalworking needs.

7.3 Where to Source Genuine Parts

Genuine Hossfeld Bender parts can be sourced directly from the official Hossfeld Manufacturing Co. website or through authorized dealers. Additionally, online marketplaces like Vintage Machinery and specialized tool catalogs offer authentic components. Ensure to verify the seller’s authenticity to avoid counterfeit items. For older models, historical documents and vintage catalogs provide valuable resources for locating compatible parts. Always prioritize genuine components to maintain performance and longevity of the machine.

Safety Guidelines

Always follow general safety practices, use protective gear, and be aware of emergency procedures to ensure safe operation of the Hossfeld Bender.

8.1 General Safety Practices

Adhering to safety guidelines is crucial when operating the Hossfeld Bender. Always wear protective gear, ensure proper machine setup, and keep loose clothing tied back. Avoid handling hot or sharp materials without gloves. Maintain a clean workspace to prevent accidents. Never bypass safety features or ignore operational guidelines. Regularly inspect tools and accessories for wear. Follow recommended practices for material handling and bending techniques to ensure a safe working environment. Proper training and awareness are essential for safe operation.

8.2 Emergency Procedures

In case of emergencies, disconnect the power immediately and activate the emergency stop button. Ensure all moving parts have stopped before approaching the machine. For injuries, provide first aid and seek medical help if necessary. Keep a fire extinguisher nearby and evacuate the area if a fire occurs. Regularly review emergency procedures with operators to ensure preparedness. Always maintain a first aid kit and emergency contact list within easy reach. Quick action and proper training can prevent minor incidents from escalating into serious accidents.

8.3 Protective Gear Recommendations

Always wear safety glasses or goggles to protect eyes from debris. Steel-toe boots and gloves are essential for hand and foot protection. Hearing protection, such as earplugs, is recommended in noisy environments. Use a face shield when handling sharp or heavy materials. Ensure loose clothing is secured to avoid entanglement with moving parts. Proper protective gear minimizes injury risks and ensures safe operation of the Hossfeld Bender. Regularly inspect gear for wear and tear, replacing items as needed to maintain effectiveness.

Compatibility with Other Machines

The Hossfeld Bender is compatible with various machinery, enhancing workflow efficiency. Adapters ensure seamless integration, making it suitable for diverse workshop setups and projects.

9.1 Integration with Other Workshop Equipment

The Hossfeld Bender integrates seamlessly with various workshop machinery, optimizing workflow and efficiency. Adapters and converters enable compatibility with different equipment, allowing for versatile operations across projects. This integration enhances productivity by streamlining tasks, making it an essential component in modern workshop setups. The ability to work alongside other machines ensures that users can handle complex bending tasks with ease, contributing to overall operational success.

9.2 Adapters and Converters for Versatility

Adapters and converters for the Hossfeld Bender enhance its versatility, allowing it to work with diverse materials and projects. These accessories expand the machine’s capabilities, enabling users to handle complex bends and unique requirements. By incorporating adapters, the bender can seamlessly adapt to different workshop needs, ensuring flexibility and efficiency. Converters further extend its functionality, making it suitable for a wide range of tasks. This adaptability ensures the Hossfeld Bender remains a valuable tool in various industrial and workshop settings.

9.3 Tips for Optimizing Workflow

Optimizing workflow with the Hossfeld Bender involves planning tasks, organizing tools, and maintaining machine efficiency. Regularly review project requirements to ensure proper tooling setup. Keep essential accessories within reach to minimize downtime. Schedule maintenance checks to prevent operational delays. By streamlining processes and leveraging the bender’s adaptability, users can achieve higher productivity and precision in their work. Proper organization and preparation are key to maximizing efficiency and workflow smoothness.

Historical and Technical Background

The Hossfeld Bender, developed by Hossfeld Manufacturing Co., has a rich history dating back to the mid-20th century. Known for its durability and versatility, it became a cornerstone in metalworking and automotive industries, evolving over decades to meet modern demands with enhanced designs and technological advancements.

10.1 History of Hossfeld Manufacturing Co.

Hossfeld Manufacturing Co. emerged in the early 20th century, specializing in innovative metalworking tools. Their iconic Hossfeld Bender, introduced in the 1940s, revolutionized the industry with its versatility and durability. The company’s commitment to quality and user-centric design helped establish it as a trusted name in workshops and factories worldwide. This legacy continues to shape the evolution of their products, ensuring they remain indispensable in modern manufacturing.

10.2 Evolution of the Hossfeld Bender Design

The Hossfeld Bender’s design has evolved significantly since its introduction in the 1940s. Early models focused on basic functionality, while later versions incorporated improved materials and mechanisms. The No. 1 and No. 2 models introduced enhanced versatility, catering to diverse metalworking needs. Modern designs emphasize precision, durability, and user-friendly features, ensuring compatibility with various projects. Continuous innovation has solidified the Hossfeld Bender’s reputation as a reliable tool in workshops and industries worldwide.

10.3 Technological Advancements in Recent Models

Recent Hossfeld Bender models feature enhanced compatibility with various materials and projects, offering improved precision and durability. Advanced tooling options, such as the Flat-Face Radius Block and Bulldozer Die, expand capabilities. Digital documentation and updated manuals provide clearer instructions, ensuring optimal performance. These advancements reflect Hossfeld’s commitment to innovation, making their benders indispensable for modern metalworking needs while maintaining their reputation for reliability and versatility in workshops and industries worldwide.

Resources and Support

The Hossfeld Bender Manual is supported by official documentation, online communities, and customer service. These resources provide troubleshooting, parts lists, and technical advice, ensuring optimal machine performance.

11.1 Official Documentation and Manuals

The official Hossfeld Bender manual offers detailed instructions and schematics for models like No. 1 and No. 2. It includes parts lists, maintenance guides, and operational tips. Available as PDF downloads, these manuals are essential for troubleshooting and ensuring proper machine use. They cover installation, advanced techniques, and safety protocols, making them indispensable for users seeking to maximize their Hossfeld Bender’s capabilities and longevity.

11.2 Online Communities and Forums

Online communities and forums are invaluable resources for Hossfeld Bender users. Platforms like Vintage Machinery and specialized tool forums host discussions, offering advice and troubleshooting tips. Enthusiasts share experiences, solutions, and modifications, fostering a supportive environment. These communities often provide access to rare manuals and historical documents. Active engagement helps users optimize their machines and address challenges, ensuring they get the most out of their Hossfeld Bender.

11.3 Customer Service and Technical Support

The Hossfeld Bender Manual is supported by official documentation, including parts lists and maintenance guides. Customer service offers technical assistance, ensuring users can address issues promptly. Genuine parts are available through authorized dealers, maintaining machine performance. This comprehensive support ensures the Hossfeld Bender operates efficiently, meeting all metal bending and fabrication requirements.

The Hossfeld Bender Manual is a valuable resource for metal fabrication, detailing operation, maintenance, and safety. It ensures efficient bending for projects, covering models like No. 1 and No. 2, helping users maximize their bending tasks effectively.

12.1 Summary of Key Points

The Hossfeld Bender Manual provides a detailed guide for operation, maintenance, and safety. It covers models like No. 1 and No. 2, offering versatility for various materials and projects. Essential tools and accessories enhance functionality, while clear instructions ensure efficient bending tasks. Safety guidelines and troubleshooting tips are emphasized to prevent accidents and extend machine longevity. The manual is a comprehensive resource for maximizing the Hossfeld Bender’s capabilities in metal fabrication and workshops.

12.2 Final Tips for Maximizing the Hossfeld Bender’s Potential

To maximize the Hossfeld Bender’s potential, always follow the manual’s guidelines for setup and operation. Regularly inspect and maintain the machine to ensure optimal performance. Experiment with different dies and materials to explore its full capabilities. Keep the workspace organized and follow safety protocols to avoid accidents. Familiarize yourself with troubleshooting tips to address common issues promptly. By mastering these practices, you can achieve precise, professional results and extend the machine’s lifespan for years of reliable service.