CDI Electronics is a leading provider of marine ignition systems‚ specializing in Capacitive Discharge Ignition (CDI) technology. This guide offers a comprehensive approach to diagnosing and resolving CDI-related issues‚ ensuring reliable engine performance and peak functionality.

1.1 Overview of CDI Electronics

CDI Electronics is a prominent manufacturer of marine ignition systems‚ specializing in Capacitive Discharge Ignition (CDI) technology. Established in 1989‚ the company has become a trusted name in the industry‚ providing high-quality ignition components for outboard and stern drive engines. Their product lineup includes power packs‚ stators‚ and trigger modules‚ designed to enhance engine performance and reliability; CDI systems are known for their efficient energy storage and rapid discharge‚ enabling consistent spark generation for optimal combustion. With a strong focus on innovation and customer support‚ CDI Electronics offers comprehensive troubleshooting guides and diagnostic tools to help technicians and enthusiasts resolve issues effectively. Their commitment to quality and durability ensures prolonged system longevity and peak functionality.

1.2 Importance of Troubleshooting in CDI Systems

Troubleshooting in CDI systems is essential for maintaining optimal engine performance and preventing costly repairs. CDI systems‚ which store and discharge electrical energy to generate sparks‚ can fail due to wiring issues‚ faulty components‚ or sensor malfunctions. Ignoring these problems can lead to engine misfires‚ reduced power‚ and even complete system failure. Regular troubleshooting helps identify issues early‚ ensuring reliable operation and extending the lifespan of the ignition system. Additionally‚ it enhances safety by addressing potential electrical hazards. Effective troubleshooting also minimizes downtime‚ allowing for quicker resolutions and getting your marine engine back in operation efficiently. By understanding and resolving CDI issues promptly‚ you can maintain peak performance and avoid unnecessary financial losses.

1.3 Scope of the Guide

This guide provides a detailed‚ structured approach to troubleshooting CDI electronics‚ covering essential steps‚ tools‚ and techniques. It addresses common issues like no spark‚ erratic sparks‚ and kill switch problems‚ offering practical solutions. The guide emphasizes safety precautions‚ such as disconnecting batteries and handling components carefully. It also explores advanced methods like signal tracing and voltage drop measurements. Additionally‚ it highlights maintenance practices to prevent future issues. By following this guide‚ users can diagnose and resolve problems efficiently‚ ensuring their CDI system operates reliably. The content is tailored for both novices and experienced technicians‚ making it a comprehensive resource for anyone working with CDI electronics.

General Troubleshooting Information

Troubleshooting CDI systems involves systematic steps‚ starting with visual inspections and basic tests. Check for broken wires‚ use a multimeter for voltage checks‚ and consult a CDI meter for accurate readings.

2.1 Basic Steps in CDI Troubleshooting

The fundamental approach to diagnosing CDI issues begins with disconnecting the kill wire to isolate the system. Next‚ inspect all wiring for damage or wear. Use a multimeter to measure voltage and resistance‚ ensuring connections are within specified ranges.Employ a CDI meter with a peak reading voltage adapter to assess the stator’s DVA voltage‚ comparing it against manufacturer guidelines. If no spark is detected‚ check the ignition coil and spark plugs. These initial steps help pinpoint potential faults‚ guiding further detailed analysis for effective resolution.

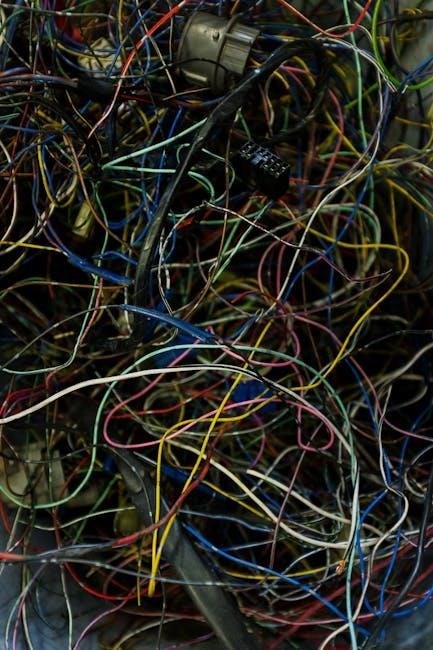

2.2 Identifying Common Symptoms

Common symptoms of CDI system issues include no spark on any cylinder‚ erratic spark patterns‚ or complete system failure. Engines may exhibit misfires‚ rough running‚ or a lack of power. Faulty kill switch circuits can prevent proper shutdown‚ while damaged wiring or sensors may cause intermittent performance problems. Additionally‚ worn or corroded connections can lead to voltage drops‚ affecting ignition consistency. Identifying these symptoms early is crucial for preventing further damage. By systematically diagnosing these indicators‚ technicians can pinpoint root causes‚ such as faulty components or wiring issues‚ and apply targeted solutions to restore optimal functionality. Early detection ensures efficient and effective troubleshooting.

2.3 Understanding DVA (Digital Voltage Adapter)

The Digital Voltage Adapter (DVA) is a critical component in CDI systems‚ enabling accurate voltage measurement and ensuring proper ignition function. It adapts stator output to the CDI unit‚ stabilizing voltage for consistent spark production. The DVA must be tested using a CDI meter with specific adapters‚ such as the CDI 511-9773‚ to measure peak voltage. Proper DVA function is essential for diagnosing issues like low voltage or open circuits. Understanding its role helps technicians interpret test results effectively‚ ensuring precise troubleshooting and maintaining optimal engine performance. Regular DVA checks are recommended to prevent ignition failures and ensure reliable operation of the CDI system. Accurate DVA measurements are vital for identifying and resolving underlying electrical issues efficiently.

Essential Tools and Equipment

Essential tools include a multimeter‚ CDI meter‚ peak reading voltage adapter‚ and wiring diagrams. These help diagnose and repair CDI systems efficiently and accurately.

3.1 Multimeter for Voltage and Resistance Tests

A multimeter is crucial for measuring voltage‚ resistance‚ and continuity in CDI systems. It helps identify faulty components like stators‚ triggers‚ and wiring. Use it to check DVA voltage‚ ensuring readings align with manufacturer specifications. For voltage tests‚ set the multimeter to DC or AC mode‚ depending on the circuit. Resistance tests help detect short circuits or open connections. Always ensure the multimeter is calibrated and set to the correct range before testing. Proper use of a multimeter is essential for accurate diagnostics and safe troubleshooting of CDI electronics.

3.2 CDI Meter and Peak Reading Voltage Adapter

The CDI meter‚ combined with a Peak Reading Voltage Adapter (PRVA)‚ is essential for measuring Digital Voltage Adapter (DVA) readings in CDI systems. This tool provides precise voltage measurements‚ helping diagnose issues like stator or trigger faults. The PRVA ensures accurate peak voltage detection‚ crucial for assessing the system’s performance. By connecting the CDI meter to the stator’s output‚ technicians can verify if voltage levels fall within manufacturer specifications. This diagnostic process is vital for identifying faulty components and ensuring reliable ignition system operation. Always use the correct adapter model‚ such as the CDI 511-9773‚ to maintain measurement accuracy and avoid system damage during testing.

3.3 Other Necessary Tools

Beyond the multimeter and CDI meter‚ several other tools are crucial for effective CDI system troubleshooting. A wire harness tester helps identify breaks or shorts in wiring‚ while an oscilloscope can analyze complex electrical signals. A circuit tester is useful for verifying continuity and isolating faulty connections. Additionally‚ a set of insulated screwdrivers and pliers prevents accidental short circuits. A heat-resistant work mat and safety goggles are essential for protecting against electrical arcs or component failures. For advanced diagnostics‚ a signal generator may be required to simulate input signals. These tools collectively ensure a thorough and safe troubleshooting process‚ helping technicians pinpoint issues efficiently and accurately. Their proper use is vital for maintaining system reliability and performance.

Safety Precautions

Always disconnect the battery before starting work. Use insulated tools to prevent electric shock. Avoid static discharge by grounding yourself. Ensure a safe‚ well-ventilated workspace.

4.1 Disconnecting the Battery

Disconnecting the battery is a critical first step in any CDI troubleshooting process to ensure safety and prevent accidental engine start-ups. Locate the battery and turn off all electrical components. Use an appropriate wrench to loosen the terminal bolts. Remove the negative (black) cable first‚ followed by the positive (red) cable. Set the cables aside to prevent accidental reconnection. This step prevents electrical shocks and ensures the system is de-energized. Always double-check that the battery is fully disconnected before proceeding with any repairs or inspections. If unsure‚ use a multimeter to verify no voltage is present. Properly insulate the terminals to avoid short circuits. Safety should always be your top priority when working with electrical systems.

4.2 Handling Electrical Components Safely

When working with CDI electronics‚ always handle electrical components with care to avoid damage or injury. Start by disconnecting the battery to eliminate power sources. Use a multimeter to verify no voltage is present before touching any components. Wear insulated gloves and ensure the work area is dry to prevent electrical shocks. Avoid touching sensitive electronics directly‚ as static discharge can damage components. Ground yourself by touching a metal object or wear an anti-static wrist strap. Use insulated tools to prevent short circuits. Never force connections or components‚ as this can cause irreversible damage. Always follow the manufacturer’s guidelines for handling specific parts‚ such as the CDI module or stator. Proper handling ensures both personal safety and the integrity of your system.

4.3 Avoiding Static Discharge

Static discharge can severely damage sensitive CDI electronics components. To prevent this‚ ground yourself by touching a metal object or wear an anti-static wrist strap connected to a grounded surface. Work on a conductive surface‚ such as an anti-static mat‚ to dissipate static electricity. Avoid walking on carpets or rubbing synthetic fabrics‚ as these can generate static. Handle components by the edges or terminals‚ avoiding direct contact with sensitive circuitry. Store components in anti-static bags or protective packaging when not in use. Use insulated tools to minimize the risk of static transfer. By taking these precautions‚ you can protect your CDI system from irreversible damage caused by static discharge.

Common Issues and Solutions

This section addresses common CDI issues‚ such as no spark‚ erratic spark‚ and kill switch problems‚ providing clear diagnostic steps and effective solutions to restore engine performance.

5.1 No Spark on Any Cylinder

When no spark is present on any cylinder‚ start by disconnecting the kill wire at the CDI pack. Check for broken or bare wires in the CD‚ stator‚ and trigger components. Using a CDI meter with a peak reading voltage adapter‚ measure the DVA voltage of the stator‚ ensuring it falls within the specified range. If the stator voltage is low‚ inspect the stator for damage or corrosion. Additionally‚ verify the kill switch circuit for faults‚ as an active kill signal can prevent sparking. If issues persist‚ consider replacing faulty components or consulting a professional technician to ensure proper system functionality and safety.

5.2 Erratic Spark or Misfires

Erratic sparks or misfires in a CDI system can stem from faulty wiring‚ corrupted signals‚ or defective components. Begin by inspecting the kill switch circuit and ensuring it functions correctly. Check the DVA voltage using a CDI meter and peak reading adapter to confirm it matches manufacturer specifications. Corroded or loose connections in the stator‚ trigger‚ or spark plug wires can disrupt the ignition process. Clean or replace these components as needed. Additionally‚ test the spark plugs for wear or fouling‚ as this can cause inconsistent firing. If misfires persist‚ consider signal tracing to identify interference or faulty sensors. Addressing these issues promptly ensures reliable engine operation and prevents further damage to the system.

5.3 Kill Switch Circuit Problems

Kill switch circuit issues can prevent the engine from firing or cause intermittent operation. To diagnose‚ disconnect the kill wire at the CDI pack and retest. If the engine ignites‚ the kill circuit is faulty‚ potentially due to a defective keyswitch‚ harness‚ or shift switch. Inspect the kill wire for breaks or short circuits and ensure proper connectivity. Measure voltage between the kill wire and engine ground to verify the circuit’s integrity. A malfunctioning kill switch or related components may require replacement. Addressing these issues ensures the kill switch functions correctly‚ maintaining safety and reliable engine performance. Always refer to the manufacturer’s guidelines for specific testing procedures and component replacement.

Advanced Troubleshooting Techniques

Advanced techniques involve signal tracing‚ voltage drop measurements‚ and component-level testing to identify complex issues in CDI systems‚ ensuring precise diagnostics for optimal performance and reliability.

6.1 Signal Tracing and Analysis

Signal tracing and analysis are critical for diagnosing complex issues in CDI systems. By monitoring electrical signals‚ technicians can identify anomalies in the ignition coil‚ stator‚ or trigger. Using an oscilloscope‚ one can visualize waveform patterns to detect irregularities such as noise or voltage spikes. This method is particularly useful for tracing intermittent faults that are challenging to replicate. Proper signal tracing requires a thorough understanding of the system’s wiring diagram and expected signal parameters. By comparing measured signals to manufacturer specifications‚ technicians can pinpoint faulty components or wiring issues. This advanced technique ensures accurate troubleshooting‚ leading to efficient repairs and prolonged system lifespan.

6.2 Voltage Drop Measurements

Voltage drop measurements are essential for identifying electrical circuit issues in CDI systems. Using a multimeter‚ measure voltage drops across connections‚ wires‚ and components under load. High voltage drops indicate poor connections‚ corrosion‚ or faulty wiring. For example‚ a significant drop at the stator or trigger connector suggests a potential issue. Compare readings to manufacturer specifications to determine if components are within acceptable ranges. This method is particularly effective for diagnosing intermittent problems caused by loose or corroded connections. By isolating the source of the voltage drop‚ technicians can pinpoint and repair the root cause‚ ensuring reliable system performance and preventing further malfunctions. Regular voltage drop testing is a proactive approach to maintaining CDI system health.

6.3 Component-Level Testing

Component-level testing involves examining individual parts of the CDI system to identify faults. Start by testing the stator‚ trigger‚ and ignition coil using specialized tools like the CDI meter and DVA adapter. Measure resistance and voltage levels to ensure they align with manufacturer specifications. If the stator or trigger shows abnormal readings‚ it may indicate internal damage. For the ignition coil‚ check for proper spark output using a spark tester. Additionally‚ inspect the kill switch and wiring harness for continuity and shorts. By isolating and testing each component‚ technicians can accurately diagnose issues and replace faulty parts‚ ensuring the system operates efficiently. This detailed approach is crucial for resolving complex or intermittent CDI system malfunctions effectively.

Maintenance and Prevention

Regular maintenance is key to preventing CDI system issues. Inspect wiring‚ clean connections‚ and replace worn components. Use diagnostic tools to ensure optimal performance and longevity.

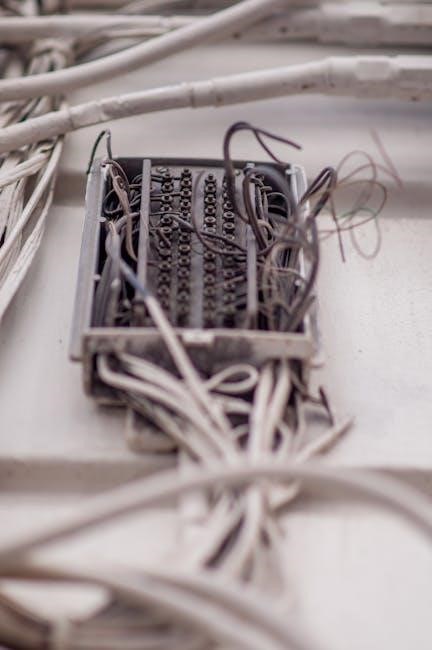

7.1 Regular Inspection of Wiring and Connections

Regular inspection of wiring and connections is crucial for maintaining the integrity of your CDI system. Start by visually examining all wires for signs of damage‚ such as fraying‚ cuts‚ or burn marks. Pay particular attention to connections at the stator‚ trigger‚ and coil. Use a multimeter to check for continuity and resistance‚ ensuring there are no opens or shorts. Clean all terminals and connectors to prevent corrosion‚ which can disrupt electrical signals. Tighten any loose connections to maintain proper conductivity. These routine checks can help prevent issues before they arise‚ ensuring reliable ignition performance and avoiding costly repairs down the line.

7.2 Cleaning and Replacing Spark Plugs

Spark plugs play a critical role in the proper functioning of your CDI system. Regular cleaning and replacement are essential to ensure consistent ignition performance. Start by removing the spark plugs using a spark plug socket and inspecting them for wear or fouling. Clean the plugs with a wire brush and sandpaper if they are salvageable. If damaged or excessively worn‚ replace them with new ones matching the manufacturer’s specifications. Always gap the new spark plugs correctly before installation. Refer to your service manual for the recommended torque specifications when reinstalling. Properly maintained spark plugs will help prevent misfires and ensure optimal engine operation‚ reducing the likelihood of CDI system issues.

7.3 Updating Software and Firmware

Updating the software and firmware of your CDI system is crucial for maintaining optimal performance and addressing any potential bugs or compatibility issues. Regularly check the manufacturer’s website for the latest updates specific to your CDI model. Download the updates using the provided software tools and follow the installation instructions carefully. Ensure the system is disconnected from the battery and all other components during the update process to prevent interruptions. After completion‚ test the system thoroughly to confirm proper functionality. Keeping your CDI system up to date ensures enhanced reliability‚ improved compatibility‚ and access to the latest features and improvements.

Resources and Support

Manufacturer guidelines‚ online forums‚ and professional support are essential resources for troubleshooting CDI systems‚ ensuring access to expert knowledge and effective solutions.

8.1 Manufacturer Guidelines and Manuals

Manufacturer guidelines and manuals are indispensable resources for troubleshooting CDI systems. They provide detailed instructions‚ diagrams‚ and specifications tailored to specific models. These documents often include step-by-step procedures for diagnosing common issues‚ such as no spark conditions or erratic ignition. By following the manufacturer’s recommendations‚ users can ensure safe and effective repairs. Many manuals also contain DVA charts and voltage drop measurements‚ which are critical for advanced troubleshooting. Additionally‚ manufacturers like CDI Electronics offer comprehensive guides‚ such as the “Practical Outboard Ignition Troubleshooting Guide‚” which covers various marine applications. These resources are updated regularly‚ reflecting the latest technical advancements and ensuring users have access to accurate information.

8.2 Online Forums and Communities

Online forums and communities are invaluable for CDI electronics troubleshooting‚ offering real-world insights and shared experiences. Platforms dedicated to marine electronics and ignition systems provide a space for users to discuss common issues and solutions. Many enthusiasts and professionals share detailed repair stories‚ including steps taken to resolve problems like no spark conditions or faulty kill switches. These communities often feature threads with DVA voltage measurements and wiring diagrams‚ which can be instrumental in diagnosing complex issues. Additionally‚ forums allow users to seek advice from experienced technicians‚ fostering a collaborative environment for problem-solving. Regularly updated discussions ensure access to the latest troubleshooting techniques and tools‚ making them a dynamic resource for CDI system maintenance and repair.

8.3 Professional Assistance

When troubleshooting CDI electronics becomes too complex‚ seeking professional assistance is the most reliable solution. Certified technicians specializing in marine electronics have the expertise to diagnose and repair intricate issues. CDI Electronics offers direct customer support through their hotline (1.800.467.3371) and technical support (1.866.423.4832)‚ providing immediate guidance for specific problems. Additionally‚ authorized distributors and marine repair shops can offer hands-on assistance‚ ensuring accurate diagnoses and repairs; For critical issues like no spark conditions or advanced component failures‚ consulting a professional is essential to avoid further damage. Their specialized tools and in-depth knowledge guarantee efficient resolution‚ making professional assistance indispensable for maintaining your CDI system’s optimal performance and longevity.

This guide provides a comprehensive approach to troubleshooting CDI electronics‚ emphasizing safe practices‚ essential tools‚ and advanced techniques. Regular maintenance and professional support ensure optimal system performance and longevity.

9.1 Summary of Key Points

This guide provides a comprehensive approach to troubleshooting CDI electronics‚ covering essential tools‚ safety practices‚ and advanced techniques. Key points include identifying common symptoms like no spark or erratic ignition‚ using multimeters and CDI meters for diagnostics‚ and understanding the role of the DVA. Regular maintenance‚ such as inspecting wiring and replacing spark plugs‚ is crucial for preventing issues. Additionally‚ updating software and firmware ensures system compatibility and performance. Safety precautions‚ including disconnecting batteries and avoiding static discharge‚ are emphasized throughout. By following these guidelines‚ users can effectively diagnose and resolve CDI system problems‚ ensuring reliable engine operation and extending system lifespan. Professional support and resources are also highlighted for complex or unresolved issues.

9.2 Encouragement for Further Learning

Continuing education is vital for mastering CDI electronics troubleshooting. Explore advanced diagnostic techniques‚ such as signal tracing and component-level testing‚ to deepen your understanding. Stay updated on the latest tools and technologies‚ like DVA adapters and multimeters‚ to enhance your troubleshooting efficiency. Engage with online forums and manufacturer resources‚ such as CDI Electronics’ manuals and guides‚ to gain insights from experts. Practical experience combined with theoretical knowledge will refine your skills. Encourage experimentation with different testing methods and explore specialized topics like firmware updates and system optimization. By committing to lifelong learning‚ you’ll become proficient in resolving even the most complex CDI issues‚ ensuring your marine ignition systems operate at peak performance.

Additional Resources

For further learning‚ explore Recommended Reading and the Diagnostic Tools Catalog. Visit www;cdielectronics.com for detailed guides‚ manuals‚ and Contact Information for Support.

10.1 Recommended Reading

For in-depth knowledge‚ refer to the Practical Outboard Ignition Troubleshooting Guide and the CDI Electronics Troubleshooting Manual. These resources provide detailed step-by-step solutions‚ DVA charts‚ and application data. The 8th Edition of the troubleshooting guide is particularly recommended for its comprehensive coverage of marine ignition systems. Additionally‚ explore downloadable diagrams and repair manuals available on www.cdielectronics.com. These materials are designed to help technicians and enthusiasts alike master CDI system diagnostics and maintenance. They offer insights into advanced techniques like signal tracing and voltage drop measurements‚ ensuring a thorough understanding of CDI electronics troubleshooting.

10.2 Diagnostic Tools Catalog

CDI Electronics offers a comprehensive catalog of diagnostic tools essential for troubleshooting ignition systems. The CDI Meter and Peak Reading Voltage Adapter are indispensable for measuring DVA voltage and stator performance. Multimeters‚ oscilloscopes‚ and signal tracing kits are also included to help identify faults in wiring and components. Additionally‚ the catalog features specialized tools like the CD77 Diagnostic Tool‚ designed for advanced troubleshooting. These tools are tailored to simplify the diagnostic process and ensure accurate repairs. For detailed specifications and ordering information‚ visit www.cdielectronics.com. Regularly updated‚ the catalog provides technicians and enthusiasts with the latest equipment to maintain and repair CDI systems effectively.

10.3 Contact Information for Support

For assistance with CDI Electronics troubleshooting‚ contact their dedicated support team. Call Technical Support at 1.866.423.4832 or Customer Service at 1.800.467.3371 for expert guidance. Visit their official website at www.cdielectronics.com for resources‚ manuals‚ and diagnostic tools. Additionally‚ CDI Electronics is active on various marine forums and communities‚ offering a wealth of troubleshooting tips and solutions. Their support network ensures you receive the help needed to resolve CDI system issues efficiently. Whether you’re a professional technician or a DIY enthusiast‚ CDI Electronics provides comprehensive support to keep your ignition system running smoothly.